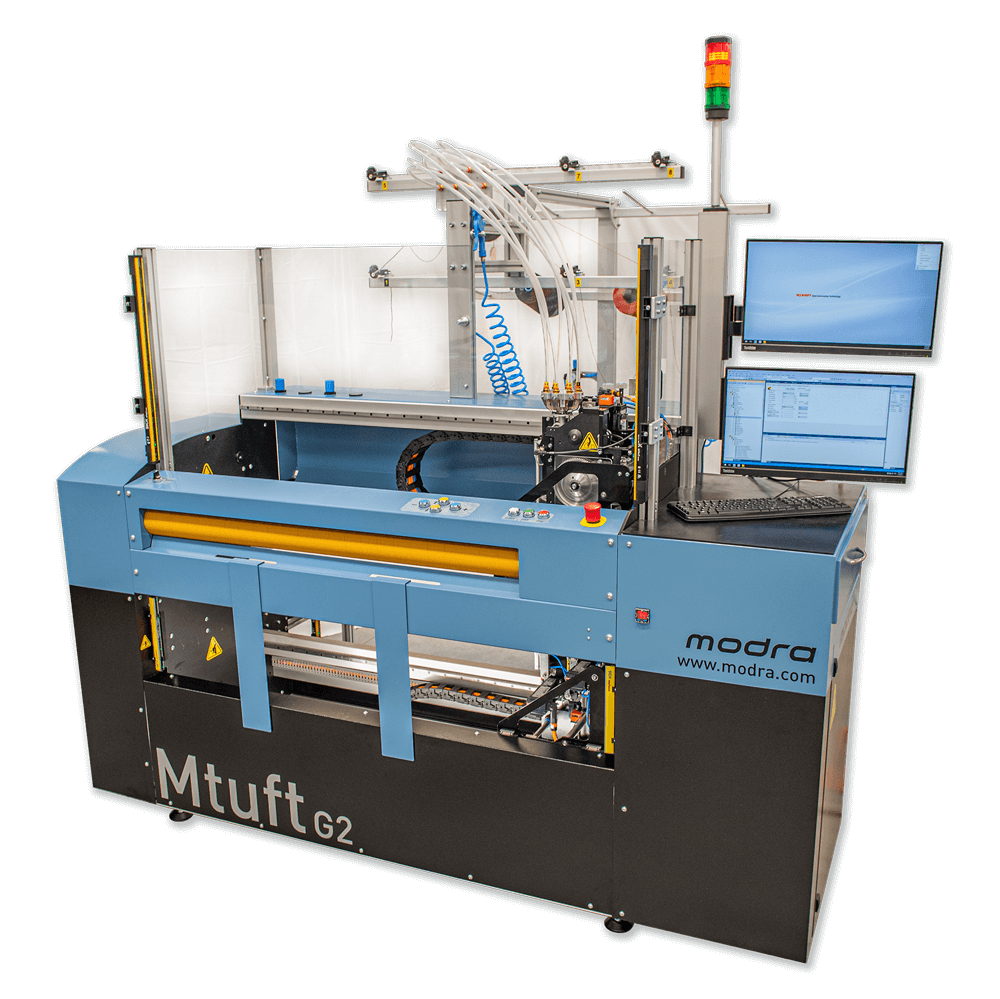

the next generation of tufted carpet sampling

8-Needle Carpet Sample Machine

Modra Technology’s next generation Mtuft introduces a range of new features based on customer feedback that make the Mtuft G2 easier to use and even more reliable. New features include Micro-Gauge for sampling ColorPoint type constructions, enhanced software control and connectivity, and production LCL and cut-loop gauge parts for improved sample quality. Free up your production machines and respond to your customers’ needs with high-quality samples.

Features:

- Powerful software to control gauge (1/16” to 1/4”), stitch rate (10 – 80 stitches / 10 cm) and variable pile heights (up to 80mm)

- NedGraphics Vision Tuft 12-month subscription included

- Loop pile construction with loop height control

- Level Cut Loop with loop height control

- Independent top and bottom head movement in the X direction means the looper is aligned to the needle for loop pule and the (conventional) hook is aligned to the needle for cut pile or end of row cut. This means production quality loop or cut without mechanical adjustment

- LCL gauge parts for production quality product

- Necessary mechanical adjustments – looper or hook stroke adjustment – are quick and easy to make

- Bed height adjustment allows small changes to the lopper and needle relative heights without changing the needle stroke.

- Beckhoff control system and industrial PC running windows 10 for longevity and reliability

- Maximum product width is 2.5m, the length can be as long as the roll of backing

We save a lot of time on the production machine and we save a lot of yarn by making the samples on the Mtuft.

Carpet manufacturer, Belgium

Benefits

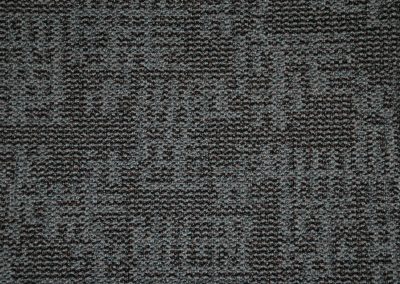

Free up your production machines and respond to your customers’ needs with high-quality samples

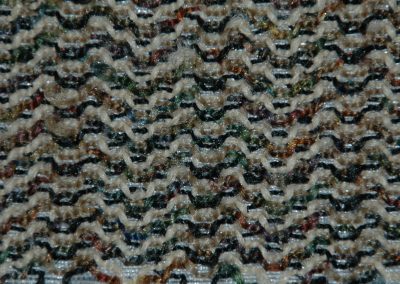

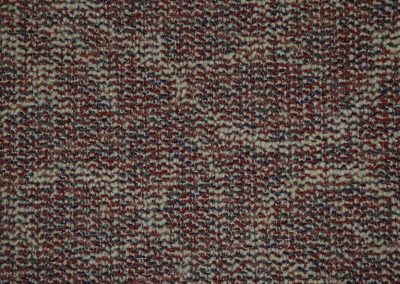

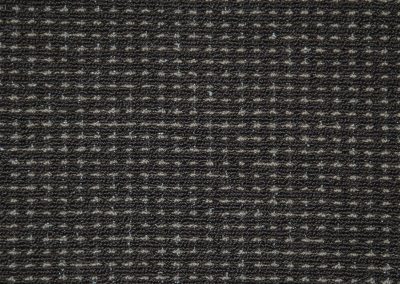

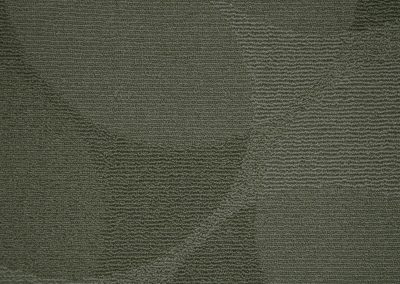

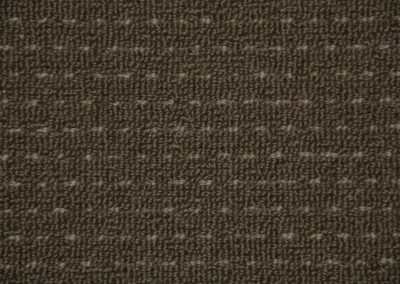

- Sample for a range of constructions, including Colorpoint, Tuftco, Cobble

- New designs and new colour ranges can be developed fast

- Unattended operation is possible due to the reliable yarn break detection system

- Sophisticated machine able to replicate what a production machine can make

- Quickly try out designs, alternative colourways and see the same design in different finished product weights

- Design software turns the Mtuft into a ‘design studio’ – samples can be made quickly, adjustments can be made quickly, allows fast client feedback

- Take product development away from your production machines

- Samples make quickly from a single package of yarn per colour

How customers use the Mtuft

- As a sales tool

- Product development

- Colour development

- Sample for new machines

- Quality control

Downloads

Product

Brochure

Technical

Specifications

Reference

List

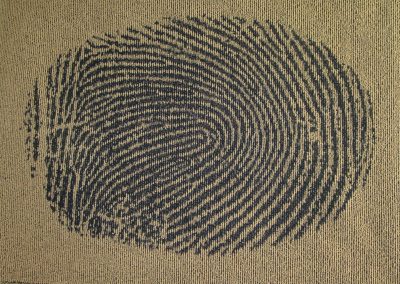

Request or Create

YOUR OWN SAMPLE

Ask us about the high-quality samples

made on the Mtuft machine.

CALL US ON +61 3 5622 3261

Model(s): TMS2XL 101, 201, 251

TECHNICAL SPECIFICATIONS:

| Mtuft G2 | TMS2XL 101 | TMS2XL 201 | TMS2XL 251 |

|---|---|---|---|

| Machine Depth (doorway clearance required) - With guards fitted - With guards removed - With guards and motors removed | Machine Depth: 930 mm / 3’ 1” 885 mm / 2’ 11” 770mm / 2’ 6” | Machine Depth: 930 mm / 3’ 1” 885 mm / 2’ 11” 770mm / 2’ 6” | Machine Depth: 930 mm / 3’ 1” 885 mm / 2’ 11” 770mm / 2’ 6” |

| Machine Height Without Creel | 1,340 mm / 4’ 5” | 1,340 mm / 4’ 5” | 1,340 mm / 4’ 5” |

| Machine Height With Creel | 2,100 mm / 6’ 11” | 2,100 mm / 6’ 11” | 2,100 mm / 6’ 11” |

| Machine Width | 2,300 mm / 7’ 7” | 3,300 mm / 10’ 10” | 3,800 mm / 12’ 6” |

| Area Required – Width | 4,100 mm / 13’ 6” | 5,100 mm / 16’ 9” | 5,600 mm / 18’ 5” |

| Area Required – Depth | 3,700 mm/ 12’ 2” | 3,700 mm/ 12’ 2” | 3,700 mm/ 12’ 2” |

| Machine Mass | 750kg / 1,650lbs | 975kg / 2,150lbs | 1,100kg / 2,425lbs |

| Shipping Crate Dimensions )LxWxD) | 2,440 x 1,050 x 1,600mm 8’ x 3’5” x 5’3” | 3,440 x 1,040 x 1,600mm 11’4” x 3’5” x 5’3” | 3,940 x 1,040 x 1,600mm 12’11” x 3’5” x 5’3” |

| Shipping Mass Total | 883kg / 1,950lbs | 1,175kg / 2,590lbs | 1,300kg / 2,870lbs |

| Noise Levels | 84 dBa at 1 metre | 84 dBa at 1 metre | 84 dBa at 1 metre |

| Compressed Air Requirements – dry, clean air | 150 lit per min @ 7 bar / 5cfm @ 100 psi | 150 lit per min @ 7 bar / 5cfm @ 100 psi | 150 lit per min @ 7 bar / 5cfm @ 100 psi |

| Power Requirements | 400-480 V AC 50 Hz 20A max, 3 Phase | 400-480 V AC 50 Hz 20A max, 3 Phase | 400-480 V AC 50 Hz 20A max, 3 Phase |

All specifications are subject to change without notice

Note: Power and air enter the creel as indicated at a height of 1,200mm / 4’. Amp cable (not supplied) at 4m / 13’.

Non-RCD supply required (Residual Current Device should not be used).

Machine can be wheeled into position by hand and is set on levelling feet when in position.

Machine should be installed in an air-conditioned environment (suitable for PC operation).

More Info

VIDEOS E-BOOKS BLOGS NEWS

Mtuft FAQs

Is it possible for Modra to run trials on the Mtuft machine prior to my purchase?

Yes, we are happy to do this. To arrange for a trial, click here.

What is the maximum number of colours possible on the Mtuft machine?

Up to 8 colours is possible.

Up to 6 colours for Micro-Gauge (ColorPoint type construction).

What types of construction is it possible to replicate on the Mtuft machine?

The Mtuft is suitable for all constructions (including ColorPoint) gauges and stitch rates.

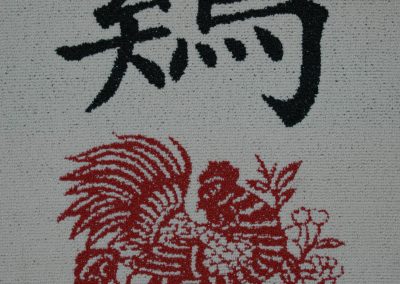

Is it possible to replicate ColorPoint type constructions?

Yes, the new G2 Mtuft model uses Micro-Gauge to replicate ColorPoint constructions.

What is Micro-Gauge?

Micro-Gauge is used for ColorPoint type constructions and allows for a maximum of 6 rows to be tufted in the one gauge space. A maximum of 6 colours is possible.

How many packages of yarn are required to make a sample?

What product widths are possible?

Does the Mtuft come with NedGraphics software?

The Mtuft includes NedGraphics Vision Tuft Advanced Controller software. This software makes it possible to create or modify NedGraphics .tft Vision Tuft patterns. The design format/output format is Open Tuft Format (.OFT) only. The NedGraphics license is valid for 12 months from the date of installation. License renewals after the initial 12 months period has expired are managed directly by NedGraphics.

Note: The NedGraphics we supply on the Mtuft is not the complete version that the design department, for example, would use. It only has machine outputs to suit the Mtuft so it shouldn’t be considered that the Mtuft version of NedGraphics can used other than to run the Mtuft.

Does the Mtuft come with conversion software?

How fast is the machine?

The maximum speed for shifted stitch is up to 10 stitches per second.

What pile height is possible?

What type of primary backing is used?

Does Modra have a system for backing Mtuft samples?

Yes, the Modra Sample Backing Press is used to apply a hotmelt backing product to the sample. Modra has a range of backing material available. To find out more, click here.

Is it possible to shear an Mtuft sample?

Yes, this is possible using the Modra Shearing System. To find out more, click here.